Introduction

When it comes to designing a commercial kitchen, the choice of material for your kitchen equipment can make a significant difference. Stainless steel has emerged as the go-to choice for chefs and restaurant owners worldwide. From durability to hygiene, stainless steel has proven to be a game-changer in the commercial kitchen equipment industry. In this article, we will explore the top 10 impacts of stainless steels on commercial kitchen equipment, helping you understand why it’s an essential material for any commercial kitchen setup.

Whether you’re outfitting a restaurant, hotel, or industrial kitchen, knowing the benefits of stainless steel will help you make informed decisions for your kitchen equipment. Let’s dive into the impacts of stainless steel on equipment such as cooking mixer machines, sweet making machines, induction cooking ranges, and much more.

Top 10 Impacts of Stainless Steels on Commercial Kitchen Equipment

-

Corrosion Resistance: The Key to Longevity

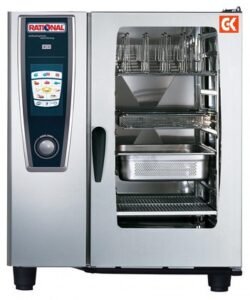

One of the most significant advantages of stainless steel material is its incredible resistance to corrosion. In a commercial kitchen, where high moisture levels and frequent cleaning are a daily necessity, corrosion can be a major issue for kitchen equipment. Stainless steel’s inherent resistance to rust ensures that your commercial kitchen equipment, such as vegetable cutting machines, tilting wet grinders, and combi ovens, stays durable over time, even in the harshest conditions.

Corrosion resistance not only keeps your kitchen equipment looking new but also reduces the need for frequent replacements. Stainless steels is highly resistant to water, acids, and other corrosive substances that are commonly found in commercial kitchens. This makes it the ideal material for a wide range of kitchen equipment, ensuring longevity and reliable performance.

-

Aesthetics: Clean and Modern Look

The visual appeal of a commercial kitchen plays an important role in creating a welcoming atmosphere for both employees and customers. Stainless steels brings a sleek, modern look to any kitchen space. It provides a shiny, polished finish that not only looks professional but also blends well with various kitchen themes.

When equipped with stainless steel sheets, your kitchen equipment, such as vegetable washers, combi ovens, and bulk cookers, will have a refined, high-end look that boosts the overall aesthetic appeal of your kitchen. The reflective surface of stainless steels adds sophistication and elegance to your kitchen, which can make a strong impression on your clients.

-

Low Maintenance: Less Work, More Productivity

One of the most notable benefits of stainless steel sheets is its low-maintenance nature. Unlike other materials that require constant care and upkeep, stainless steels is relatively easy to maintain. The smooth surface of stainless steels makes it simple to clean, ensuring your kitchen equipment remains free from dirt, stains, and food particles.

With equipment like dough kneaders, potato peelers, and rotary ovens, you’ll find that regular wiping with a cloth is often enough to maintain cleanliness. This reduces the amount of time and effort needed for maintenance, allowing your team to focus on food preparation and service.

-

Durability: Built to Last

When it comes to commercial kitchen equipment, durability is a must. Stainless steels is known for its impressive strength and ability to withstand constant use. Whether it’s the induction dosa plate or a commercial dishwasher, stainless steels is designed to endure the rigors of a busy kitchen.

The material’s resilience to impact, pressure, and heavy loads ensures that your equipment lasts for years, even in the busiest of environments. Stainless steel doesn’t warp or break easily, making it an excellent long-term investment for your kitchen.

-

Food Grade: Safety First

In any kitchen, food safety is a top priority. Stainless steels is one of the safest materials used in food preparation and storage. It meets the standards for food-grade material and is non-toxic, which means it won’t leach harmful chemicals into your food.

This is especially important for kitchen equipment like sweet making machines, instant rice grinders, and vegetable cutting machines, which come into direct contact with food. The non-reactive surface of stainless steels ensures that the food remains safe, fresh, and uncontaminated during preparation.

-

Temperature Resistance: Handling the Heat

Commercial kitchens often deal with high temperatures, whether it’s from hot ovens, induction cooking ranges, or grills. Stainless steels is highly resistant to temperature fluctuations, making it the perfect material for equipment that deals with extreme heat.

Stainless steel maintains its structural integrity under both high and low temperatures, making it ideal for equipment like induction cooking pots, bratt pans, and tilting wet grinders. This resistance to heat ensures that your equipment operates efficiently, even in high-pressure cooking situations.

-

Hygienic Preparation: Keep It Clean

In any food service environment, hygiene is critical. Stainless steels is inherently non-porous, which makes it a hygienic choice for kitchen equipment. It’s easy to clean and sanitize, preventing bacteria, mold, and other contaminants from accumulating.

With kitchen equipment like commercial dishwashers, sweets and snacks machines, and cutter mixers, cleanliness is vital for maintaining food safety standards. The non-porous surface of stainless steels ensures that your equipment is safe and sanitary, reducing the risk of cross-contamination.

-

The Bottom Line: Cost-Effective in the Long Run

While stainless steel equipment may come with a higher upfront cost, the long-term savings make it a highly cost-effective investment. The durability, low maintenance, and resistance to corrosion reduce the need for frequent repairs and replacements. Additionally, stainless steel equipment tends to have higher resale value compared to other materials.

Investing in stainless steel kitchen equipment, such as induction cooking ranges, bain maries, and commercial dishwashers, can save your business money over time, while also ensuring that your kitchen stays in top shape.

-

High Resale Value: An Asset for the Future

Another benefit of stainless steels is its high resale value. Because stainless steel is known for its durability and longevity, it often retains its value better than other materials. If you ever decide to upgrade your equipment or sell your kitchen gear, stainless steel equipment, like vegetable cutting machines, combi ovens, or dosa plate ranges, will fetch a better resale price compared to equipment made from other materials.

This makes stainless steel an even smarter investment for your kitchen in the long run.

-

Flexibility: Versatility Across Equipment

Stainless steels is incredibly versatile, making it suitable for a wide variety of commercial kitchen equipment. Whether you need a multipurpose sweet-making machine, a rotary type chapathi machine, or idly plant, stainless steels can be molded and shaped into virtually any form to meet your specific needs.

This flexibility allows manufacturers to create customized solutions tailored to the demands of modern kitchens, ensuring that your equipment performs at its best.

Why Stainless Steels is Essential for Commercial Kitchens

Stainless steel is undeniably the backbone of modern commercial kitchens. Its unique combination of durability, corrosion resistance, and ease of maintenance makes it an ideal material for all types of kitchen equipment. From induction cooking ranges to multipurpose vegetable cutting machines, stainless steels not only ensures the longevity and performance of your equipment but also promotes a clean, hygienic, and safe working environment. The sleek, modern appearance of stainless steel enhances the overall aesthetics of the kitchen, while its non-porous surface prevents contamination, making it a food-safe material for everything from sweet-making machines to commercial dishwashers.

The strength of stainless steel is unmatched, allowing kitchen equipment to withstand heavy use and extreme temperatures without compromising its structural integrity. Moreover, the versatility of stainless steel ensures it can be customized to fit the diverse needs of commercial kitchens, whether you’re preparing a large volume of food or engaging in complex cooking processes.

In addition to its functional benefits, stainless steel also offers a high resale value, ensuring that your investment will pay off in the long run. Overall, stainless steel is not just a material choice but a critical element in optimizing the efficiency, safety, and aesthetic appeal of any commercial kitchen.

Conclusion

From its corrosion resistance to its hygienic preparation and durability, stainless steels is undoubtedly the best material for commercial kitchen equipment. Whether you’re looking to invest in induction cooking ranges, commercial dishwashers, or multipurpose vegetable cutting machines, stainless steels ensures that your equipment lasts longer, performs better, and helps maintain a clean, safe kitchen environment.

At Global Kitchen India, we offer a wide range of high-quality stainless steel kitchen equipment designed to enhance your kitchen’s efficiency and performance. Ready to upgrade your kitchen equipment? Explore Global Kitchen India’s wide selection of commercial kitchen equipment today and experience the benefits of stainless steel firsthand!

FAQ

-

Why is stainless steel commonly used in commercial kitchen equipment

Stainless steels is durable, corrosion-resistant, easy to maintain, and hygienic, making it ideal for commercial kitchen equipment.

-

What types of kitchen equipment are made from stainless steel?

Common kitchen equipment made from stainless steels includes cooking mixer machines, induction ranges, vegetable cutting machines, and commercial dishwashers.

-

How does stainless steel improve hygiene in the kitchen?

Stainless steels is non-porous, making it easier to clean and sanitize, preventing bacteria and contaminants from accumulating.

-

Can stainless steel equipment be customized?

Yes, stainless steels is highly versatile and can be molded into various shapes to suit the specific needs of commercial kitchens.